Gas Furnace Ignition Systems

Lighting the furnace

Furnace ignition methods have drastically changed over the years. The need for safety and reliability has driven those changes. Furnaces manufactured today no longer have pilot lights. They are so obsolete that you rarely see one in the field.

Here we'll go through several ignition methods starting with a pilot light and ending with an electronic ignition system.

Standing pilot ignition system

Older furnaces use standing pilot lights for ignition, but standing pilot lights are no longer used in modern gas furnaces. A standing pilot light is a small burner that is continuously lit.

If the pilot flame goes out, the pilot safety shuts off the gas to both the pilot light and the main burners. This is done as a safety measure to avoid fire or explosion hazards. This is particularly true with LP gas, which is heavier than air, and could collect over a prolonged period to be a hazard.

There are 3 types of flame-proving devices that will shut off gas flow if the pilot light goes out:

Thermocouples

Bimetallic safety devices

Liquid-filled remote bulbs

As long as the pilot flame heats the flame sensor, the gas safety valve remains open, and the gas will flow when called for. The gas safety valve will close if the pilot flames go out and the flame sensor cools. In most cases, the pilot will need to be manually reset.

Intermittent pilot ignition system

Intermittent pilot lights save gas by lighting the pilot light on each call on heat and then extinguishing the pilot at the end of each heating cycle. Early 78% AFUE furnaces used intermittent pilot ignition systems. On a call for heat, these systems

open the pilot gas valve and attempt to light the pilot light

establish that the pilot has lit

open the main burner gas valve and the pilot light ignites the main burner

Many systems were developed. They differ in how the pilot light is ignited and how the pilot flame is detected. Spark igniters and hot surface igniters have both been used to light the pilot. Spark pilot igniters have the advantage of being quick and tough, but they are somewhat unreliable. Hot surface ignition is slower but more reliable. Unfortunately, hot surface igniters are quite fragile compared to spark igniters.

Mercury switches, bi-metal warp switches, and flame rectification have all been used to detect the pilot flame. Flame rectification is much faster and generally more reliable than either mercury bulbs or warp switches.

After the flame sensor detects the pilot flame, the control board then energizes the main gas valve and de-energizes the ignition circuit. This all takes place in a matter of seconds. When the call for heat is satisfied, both the pilot and main gas valves are de-energized.

Direct Spark Ignition

The direct spark-ignition system uses an electrical flame sensor rod mounted so that it has direct contact with the main burner flame. Because the gas flame will carry electrical energy by electrically charging the atoms in the gas, a current flow can be passed from the grounded burner to a positively charged flame rod.

When current is allowed to flow in only one direction, that current is said to be rectified. The flame rectifies the AC so that it flows out of the flame as pulsed 2 to 50 microamp DC. This current flow controls a circuit in the solid-state control module and keeps the gas valve energized. Flame rectification provides several unique features for a flame sensor.

For example, if the flame rod has shorted against the furnace, it will pass the AC through the furnace and the controller will not open the gas valve because pulsed DC is not present. Also, if the flame does not light, no current will flow, and the controller will not open the gas valve again. If the flame goes out, the controller will not open the gas valve. If the flame goes out, the controller will shut off the gas valve once the pulsed DC signal is lost.

Upon a call from the room thermostat, both the main gas valve and the spark igniter are activated. Allowing a predetermined time for main flame ignition, the ignition control module will shut down the lockout circuit and maintain burner operation if main flame ignition occurs in that period. The period may be from 4 to 21 seconds, depending on the model of the control module used. Generally, a higher input to the gas unit results in a shorter proving time.

The control module shuts off the gas valve if the main burner flame is not established in the set time. Many systems will wait for a minute and then make another ignition attempt. After several attempts, the system automatically locks out. To reset the circuit, the electrical power to the system must be cut off and then back on to start another cycle. A manual reset of such a system is used for maximum safety of the equipment and building.

Because this system uses the main burner assembly as the ground terminal of the spark system, the gas-burning unit must be thoroughly grounded to the electrical supply ground. It is wise and usually necessary to run a ground (green) wire from the power-distribution panel to the unit to provide this positive ground. Because the white or neutral wire is a 120/240 V supply system, it is a current-carrying wire. It is not suitable for use as a unit ground.

Hot-Surface Ignition System

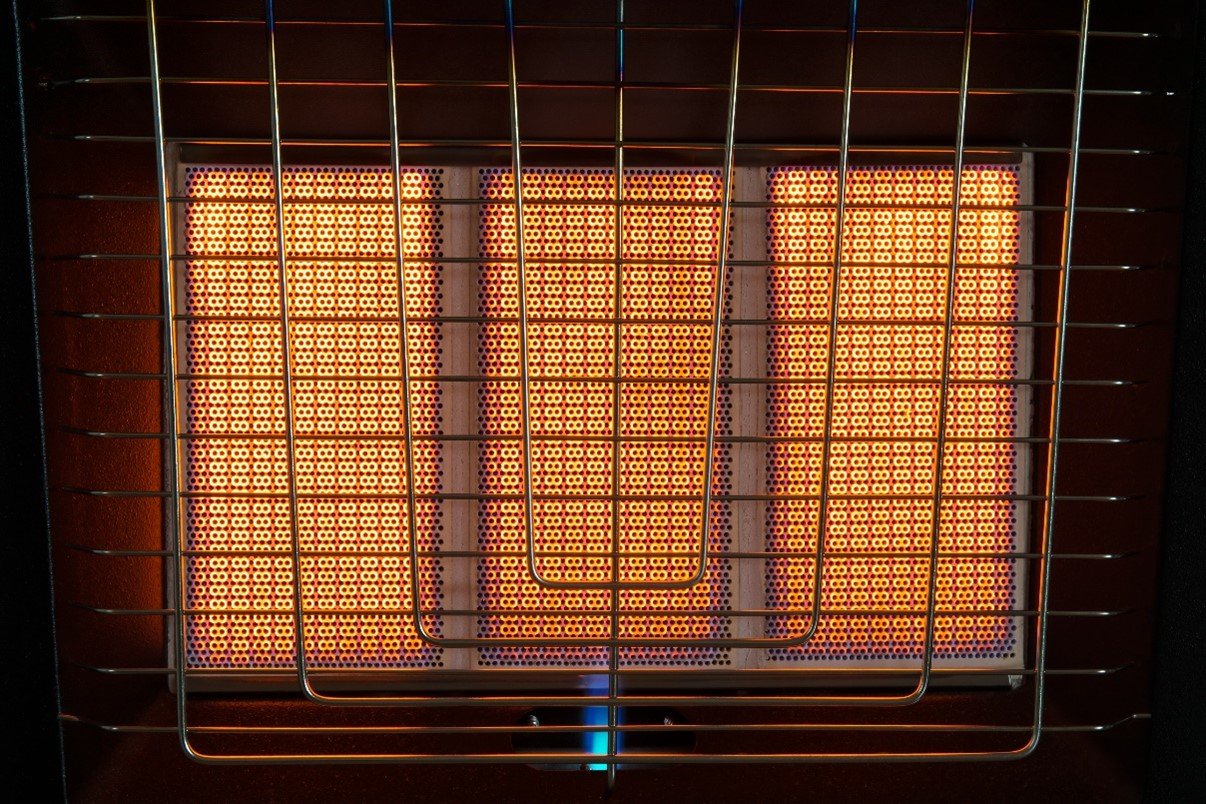

A hot-surface igniter is used for igniting the gas burners on many of the latest furnaces. This unit is made of silicon carbide, a material that has a very high resistance to current flow and, when energized, reaches the ignition temperature of the gas. Even though it will last a long time, it is also brittle and will break easily with rough treatment.

Make sure you do not touch the silicon carbide with your bare hand because it eventually will burn out where you touch it. The control system allows this material to reach ignition temperature before the gas valve opens.

These units are powered by 120 V and draw a considerable amount of current when energized; however, they are used only a few minutes per day and therefore do not materially increase the electric bill. If the burner fails to light or the flame sensor fails to detect a flame after the gas is turned on for a few seconds, a safety lockout will occur to stop the flow of gas.

Summary of gas furnace ignition systems

As ignition systems have changed, they have become more complex and sensitive to improper care. Trained, skilled technicians are needed to work on these systems.

Being electronic, ignition systems require routine care and checks. Dirt, dust, pollen, and cobwebs can cause these systems to overheat and malfunction. Regular tune-ups are needed to maintain the reliability and efficiency of your home heating system.