Top Uses and Benefits of Flexible Conduit for Electrical Wiring

Flexible conduit is used to protect and route electrical wiring in various settings. It offers flexibility and enhanced protection, making it perfect for tight spaces and harsh environments. This article covers the types, benefits, and practical uses of flexible conduit.

Key Takeaways

Flexible conduits offer superior protection and adaptability for electrical wiring, making them suitable for various applications, including residential and industrial settings.

The lightweight, durable construction of flexible PVC conduits allows for easier handling, installation, and increased cost efficiency while providing resistance to environmental hazards.

Selecting the appropriate flexible conduit requires consideration of material compatibility, environmental conditions, and compliance with safety regulations to ensure effective and safe installations.

Understanding Flexible Conduit

Flexible conduits are an essential component in modern electrical installations, offering superior protection and flexibility compared to rigid conduit systems. These conduits are designed to safeguard electrical wiring from environmental hazards and physical damage while allowing for easy routing in tight spaces.

There are four primary types of flexible conduits:

Flexible Metallic Conduit (FMC)

Liquidtight Flexible Non-Metallic Conduit (LNFC): Composed of flexible and rigid PVC materials, enhances durability and water resistance, making it ideal for outdoor applications.

Liquidtight Flexible Metal Conduit (LFMC): Combines flexibility with moisture protection, making it suitable for industrial environments.

Flexible Metallic Tubing (FMT): Designed for smoke-tight applications with a one-piece design that simplifies installation.

One of the standout features of flexible conduits is their construction from flexible PVC. This material is known for its high impact strength, making it suitable for applications requiring resilience. Flexible PVC also exhibits excellent resistance to UV light, acids, and alkalis, enhancing its longevity in various environments. Crawford Electric Supply offers a wide range of these conduits, ensuring that you have the right product for every application.

Understanding the different types and benefits of flexible conduits is the first step towards making informed decisions for your electrical projects. Their flexibility and robust construction make them a go-to choice for numerous applications, from residential wiring to complex industrial setups.

Key Advantages of Flexible PVC Construction

One of the primary reasons flexible PVC conduits are favored in electrical installations is their lightweight nature. The benefits include:

Easier to handle and install compared to traditional materials

Significant reduction in labor time and effort

Cost savings, especially in large-scale projects where time efficiency is crucial

The durability of flexible PVC construction also stands out. These conduits are designed to withstand various harsh conditions, making them a reliable choice for outdoor installations where they might be exposed to the elements. Whether it’s extreme temperatures, heavy impacts, or constant moisture, flexible PVC conduits maintain their integrity and continue to protect electrical wiring effectively.

Another key advantage is their exceptional corrosion resistance to environmental factors such as corrosion. Flexible PVC conduits provide a robust barrier against corrosive substances, ensuring the longevity of the electrical systems they protect. This makes them particularly suitable for industrial environments where exposure to chemicals and other corrosive materials is common.

In addition to their practical benefits, the flexibility of PVC conduits allows for easier routing and installation in tight spaces. This adaptability not only simplifies the installation process but also enhances the overall safety and performance of the electrical system. Choosing flexible PVC conduits means investing in a solution that provides both immediate and long-term benefits.

Applications of Flexible Conduits in Electrical Wiring

Flexible conduits are incredibly versatile, finding applications in a wide range of electrical wiring projects. One of the most common uses is in connecting outdoor lighting systems. These conduits provide excellent protection against weather elements, ensuring that the electrical wiring remains safe and functional. The waterproof quality of flexible conduits is particularly praised, making them ideal for such outdoor applications.

In residential settings, flexible conduits are often used in hot tubs installations. They safeguard electrical wiring from moisture and temperature fluctuations, ensuring a safe and reliable connection. This application highlights the importance of using conduits that can withstand challenging environments while maintaining performance, including the use of a coil.

Industrial applications also benefit significantly from the use of flexible conduits. In these settings, conduits protect wiring from corrosive substances and mechanical damage, which are common hazards in industrial environments. The ability of flexible conduits to provide robust protection makes them an essential component in maintaining the safety and efficiency of industrial electrical systems.

The versatility of flexible conduits extends to various other applications, including protecting electrical wiring in both indoor and outdoor environments. Their adaptability and durability ensure that they can meet the demands of different projects, making them a valuable addition to any electrical installation.

Selecting the Right Flexible Conduit for Your Project

Choosing the right flexible conduit for your project requires careful consideration of several factors. Understanding the specific application requirements, including environmental conditions and flexibility needs, is crucial. For instance, if the project involves outdoor lighting, selecting a conduit that offers excellent moisture resistance and durability is essential.

Material compatibility is another critical factor. Consider the following when selecting a conduit:

The conduit must match the type of wires being used to ensure safety and functionality.

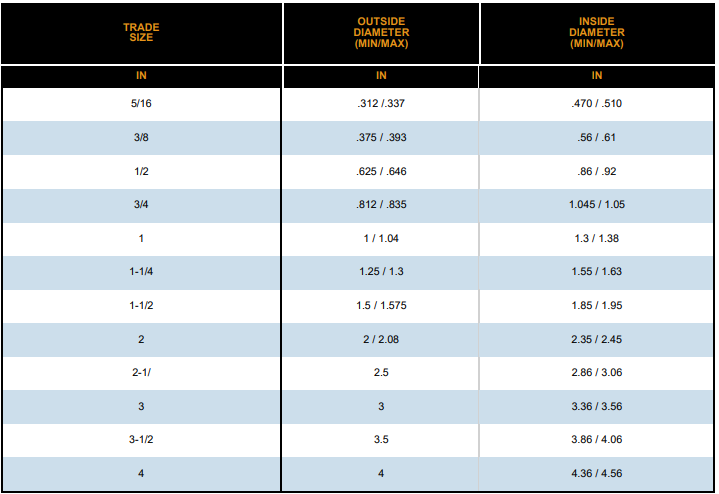

The size of the conduit should be determined based on the number and size of wires to be installed.

Allow for potential future expansions when determining conduit size.

Compliance with regulatory standards is also vital. Flexible conduits must meet various standards like UL, CSA, and NEC to ensure safety and performance in electrical installations. Compliance with the National Electrical Code (NEC) is crucial to avoid electrical failures and ensure safety. Various NEC articles govern specific types of flexible conduits, outlining their appropriate applications and safety standards. Local amendments to the NEC may impose additional compliance requirements, necessitating awareness of regional regulations.

Proper installation practices, such as maintaining bend radius and support spacing, are key to ensuring compliance and system integrity. By considering these factors, you can decide on the best flexible conduit for your project, ensuring both safety and efficiency in operation.

Tools and Accessories for Installing Flexible Conduits

Installing flexible conduits requires the right tools and accessories to ensure a secure and efficient setup. A PVC cutter is essential for achieving clean and precise cuts on flexible conduits. This tool helps in minimizing waste and ensuring that the ends of the conduit are smooth and ready for fittings.

Utility knives are also versatile tools that can help in stripping or trimming conduit materials effectively. A utility knife is handy for making quick adjustments during the installation process, ensuring that the conduits are properly utilized for use.

Using appropriate fittings is crucial for ensuring secure connections between conduits and electrical boxes. Key points include:

Selecting a conduit with compatible fittings can simplify the installation process.

Proper fittings reduce the risk of loose connections and potential electrical hazards.

Cable ties can be used to neatly secure flexible conduits in place, ensuring a tidy and organized installation.

For contractors, having a well-stocked toolkit of these essential items can make the installation process smoother and more efficient. By investing in the right tools and accessories, you can ensure that your flexible conduit installations are both safe and reliable.

Ensuring Safety and Compliance

Safety and compliance are paramount when it comes to installing flexible conduits. These conduits serve as protective solutions for electrical wires against physical damage and environmental hazards, ensuring the longevity and safety of the electrical system.

Specialty conduits, such as halogen-free and EMI/RFI shielding conduits, cater to specific environmental needs and safety standards. The material’s non-flammable properties contribute to safety in applications where fire resistance is critical and are UL rated. Understanding and complying with local electrical codes is vital to avoid safety issues and meet regulatory standards.

Installers should consider the following when working with flexible conduits:

Verify the specific regulatory requirements of the environment where flexible conduits will be used.

Use proper handling tools, such as gloves, to protect hands from sharp edges while working with conduits.

Follow grounding requirements, which vary by conduit type and length, to ensure electrical safety in installations.

By adhering to these safety and compliance guidelines, you can ensure that your flexible conduit installations are not only effective but also safe and in accordance with regulatory specifications, which certify their quality, security, controls, and permission.

Customer Reviews and Feedback

Customer feedback is a valuable source of data insight into the performance and reliability of flexible conduits. At Crawford Electric Supply, customers have expressed high satisfaction levels with the flexible conduits purchased, noting their ease of use and effectiveness in various applications. This positive review highlights the quality of our products.

Numerous reviews highlight the lightweight and adaptable nature of the flexible conduits, making them a favored choice among users. Buyers frequently commend how they can modify the durable construction of the flexible conduits, citing their ability to withstand harsh environmental conditions without compromising performance or weight. As a reviewer, I can attest to their effectiveness.

Many customers report long-lasting performance, attributing the longevity of the conduits to their high-quality materials. Users consistently mention the reliability of these conduits in their electrical setups, appreciating how they maintain effectiveness even in challenging installations for each person involved.

Experts emphasize that choosing flexible conduits from Crawford Electric Supply can lead to better project outcomes due to the quality and dependability highlighted by users. These positive reviews affect the importance of selecting high-quality materials for electrical installations.

Why Choose Crawford Electric Supply for Flexible Conduits

Crawford Electric Supply stands out as a trusted source for flexible conduits, offering a balance between performance and expense for various construction needs on any date. The product is noted for providing excellent value for money, with several customers expressing satisfaction with the quality relative to its price, making it a preferred choice for those seeking oil edgesuite solutions and an account of their needs.

Expert guidance is available at Crawford Electric Supply, including:

On-site professionals helping with code compliance and conduit selection for specific use cases

Professional-grade materials

Reliable sourcing for large projects

Deep knowledge of local building codes

Purchasing from a wholesale distributor like Crawford Electric Supply offers several advantages:

Ensures job-ready stock, reducing downtime with fast, local access to standard and specialty conduit sizes.

Known for its wide inventory and expert service.

Offers competitive rates for volume orders and contractor accounts during a purchase sale.

The central Knoxville location of Crawford Electric Supply supports fast pick-up or delivery for projects across East Tennessee. By choosing Crawford Electric Supply, you are ensuring that your projects are supported by a reliable and knowledgeable partner.

Summary

In summary, flexible conduits, particularly those made from PVC, offer numerous benefits for electrical installations. Their lightweight nature, durability, and resistance to environmental factors make them an excellent choice for various applications, from residential to industrial settings.

Selecting the right flexible conduit involves understanding the specific requirements of your project and ensuring compliance with regulatory standards. Proper tools and accessories further enhance the safety and efficiency of installations.

Crawford Electric Supply provides high-quality flexible conduits and expert guidance, ensuring that your electrical projects are completed with the utmost reliability and compliance. By choosing Crawford Electric Supply, you are investing in a trusted partner dedicated to supporting your success in every project.

Frequently Asked Questions

What are the primary types of flexible conduits available?

The primary types of flexible conduits include Flexible Metallic Conduit (FMC), Liquidtight Flexible Non-Metallic Conduit (LNFC), Liquidtight Flexible Metal Conduit (LFMC), and Flexible Metallic Tubing (FMT). Each type serves specific applications in electrical installations.

Why is flexible PVC construction preferred for conduits?

Flexible PVC construction is preferred for conduits because it is lightweight, durable, and resistant to corrosion, allowing for easy installation in tight spaces. This combination of characteristics enhances its practicality and effectiveness in various applications.

What are some common applications of flexible conduits in electrical wiring?

Flexible conduits are commonly used to connect outdoor lighting systems, hot tub installations, and in industrial settings to protect wiring from environmental hazards. Their versatility and protective capabilities make them an essential component in various electrical applications.

How do I select the right flexible conduit for my project?

To select the right flexible conduit, evaluate the application requirements, ensure material compatibility, determine the appropriate size, and verify compliance with regulatory standards. Prioritizing these factors will ensure optimal performance for your project.

Why should I choose Crawford Electric Supply for flexible conduits?

Choosing Crawford Electric Supply for flexible conduits is advantageous due to their high-quality materials, expert guidance, competitive pricing, and extensive inventory, ensuring reliable support for your electrical projects.