Heat Pump Defrost

Understanding your heat pump defrost cycle

Every HVAC system has a particular challenge overcoming environmental conditions. Heat pumps, despite their name, are susceptible to freezing up even when outdoor temperatures are above freezing.

Heat pump freezing is a very common homeowner complaint at the beginning of each heating season. When you change your thermostat to heat mode, the heat pump switches the flow of refrigerant through the system.

When this happens the indoor unit becomes the condenser and the outdoor coil acts as the evaporator. Thermal energy is picked up from the outside air and delivered to the indoor air.

Understanding your heat pump's defrost mode may prevent unneeded trouble calls and the cost associated with it. Ice buildup with negatively affect your heat pump's efficiency. Taking the necessary steps to ensure your heat pump is functioning properly will reduce your energy usage.

Heat Pump Defrost Cycle

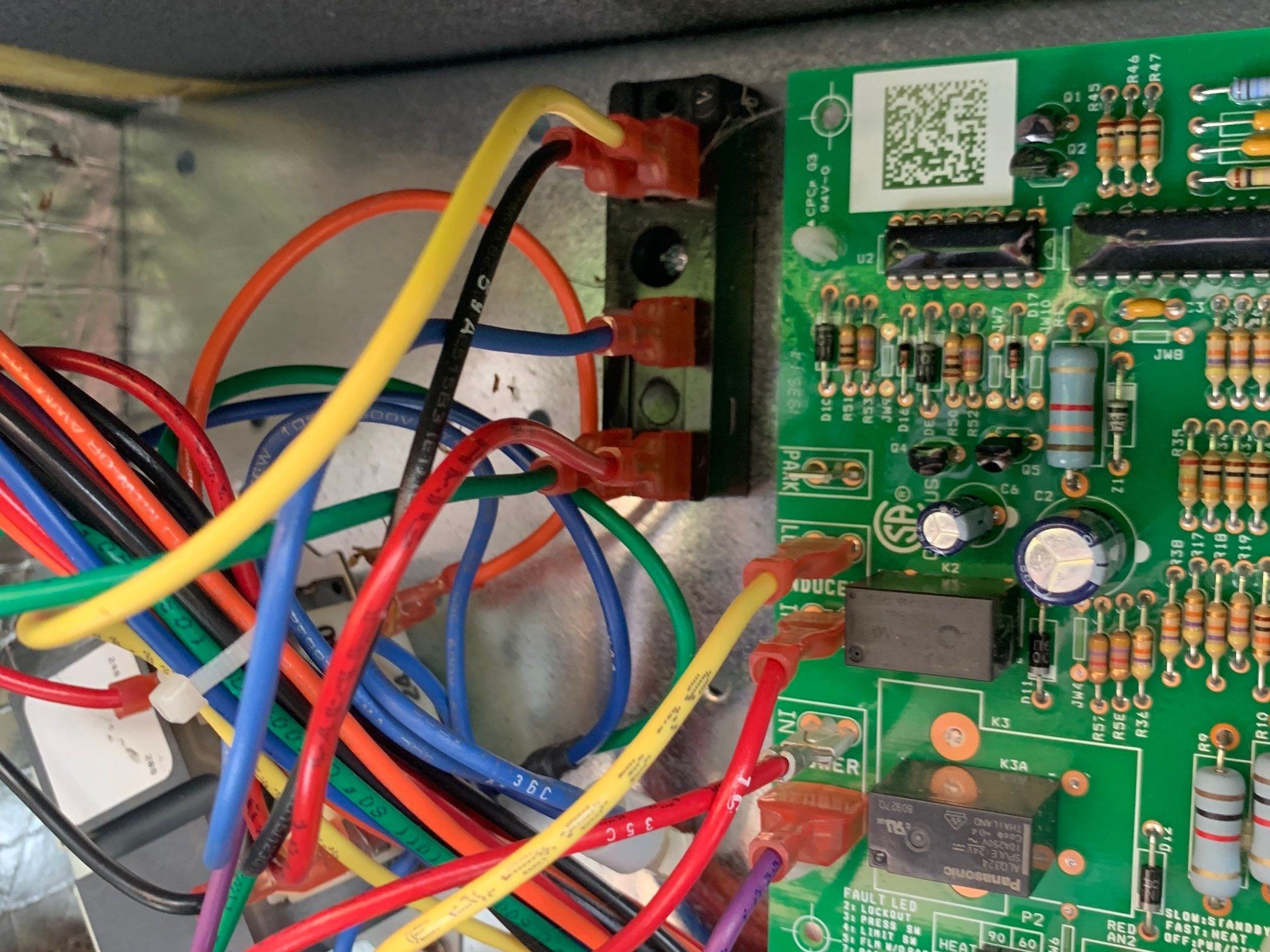

Frozen condenser caused by faulty defrost control board

Why do heat pumps need a defrost mode?

Frost forms on the heat pump outdoor coil at low ambient temperatures because it must operate below the outdoor temperature. It is important to keep it cleared of frost because the heat pump system efficiency drops when frost builds to the point that it blocks airflow.

The heat pump defrost cycle is required to melt the frost before it interferes with system operation. The defrost cycle is similar to the cooling cycle, except that the outdoor fan is de-energized and the strip heaters are energized.

The outdoor unit switches from being an evaporator to now being the condenser. This allows for hot vapor to pass through the outdoor coil to help defrost any frost buildup.

However, an adverse result of operating in this mode will be that the unit is air conditioning the house in the middle of winter!

To offset this effect, the outdoor fan is de-energized and the auxiliary heat is energized during the defrost cycle. The auxiliary heat is energized to prevent 60F air from blowing in the house.

When the defrost cycle is initiated, the reversing valve reverses to send hot gas to the outdoor coil and the outdoor fan is de-energized. In defrost mode, the indoor coil becomes an evaporator, removing heat from the indoor air.

Why your heat pump needs auxiliary heat?

Without energizing the auxiliary heat, the air delivered to the conditioned space would be cold air rather than hot air. To reduce this effect, the auxiliary heat comes on for the duration of the defrost cycle to reheat the air. The result is warm air, at 80F, instead of being cold, at 50F.

Heat pump defrost controls

The heat pump defrost must determine when to start a defrost cycle and when to stop it. Starting a defrost cycle is called initiation; stopping a defrost cycle is called termination. If the defrost cycle is not initiated frequently enough, the outdoor coil of the heat pump will become frozen over with a sheet of ice.

If the defrost cycle is initiated too often, the efficiency of the system is decreased and energy is wasted, increasing the cost of operation. Some method, in addition to temperature, must be used for initiation.

If temperature alone was used for initiation, the system would not be able to operate normally below freezing. Most defrost controls use temperature to sense when they should terminate the defrost cycle.

The two most common types of heat pump defrost controls are time temperature and temperature differential.

Time Temperature Defrost Controls

The time-initiated temperature-terminated defrost control board uses a timing circuit and an open-on-rise defrost thermostat to control the defrost cycle. The timing circuit times the amount of compressor operating time during the heating cycle.

It will not allow a defrost cycle until after a specific amount of compressor operating time. The most common defrost periods are 30, 45, 60, and 90 minutes. The defrost time period can be adjusted on the defrost board by moving a jumper or a selector switch.

Typical defrost cycle for time-temperature control

When the defrost time is reached, the timer will try to initiate the defrost cycle. However, if the temperature is not low enough, generally below 26F, the defrost thermostat will not close and the defrost cycle will not begin.

The timer will reset, and a new countdown starts until the next defrost begins. Once a defrost cycle has been started, it will continue until the defrost thermostat opens, usually somewhere around 50F.

The placement of the defrost thermostat is critical for correct operation. Its location can vary a great deal from one model unit to another. The time has a fail-safe defrost period, usually 15 to 30 minutes.

Even if the defrost thermostat fails to open after the fail-safe period of defrost operation, the defrost control terminates the defrost cycle and puts the heat pump back into heating mode.

Heat Pump Demand Defrost Controls

The major advantage of time temperature defrost controls is reliability. The main disadvantage is that forcing a defrost every hour of operation in cold weather can cause unnecessary defrosts that waste energy.

Just because the coil temperature is below freezing does not necessarily mean there is frost on the coil. A demand defrost control senses some aspect of unit operation to determine when there is actually frost on the outdoor coil.

Preferred method of demand defrost control

Methods used for demand defrost controls have included the following:

Air pressure drop across the heat pump outdoor coil

Compressor amp draw

Temperature differential

Temperature differential has proven to be the most reliable. Nearly all demand defrost controls today use the temperature differential method.

Typical defrost cycle for demand control

A temperature differential defrost control uses thermistors to sense the outdoor coil temperature and the outdoor air temperature. Under normal operating conditions, the temperature difference between the coil and the outdoor air remains fairly constant.

When the frost on the coil builds to the point that it is blocking airflow, the coil temperature starts to drop. Since only the coil temperature is dropping, the temperature difference between the coil and the air is increased.

The temperature differential control initiates a defrost whenever the difference between the coil and outdoor air increases for a prolonged period of time. Most demand defrost controls have some fail-safe period built in to force a defrost after several hours of operation below freezing.

Like time temperature controls, temperature differential controls terminate the defrost when the coil temperature has reached around 50F. They also have a fail-safe defrost operation time that will terminate a defrost cycle after 15 to 30 minutes.